The flash point, also known as the flash point, refers to the temperature at which a mixture of vapor and air on the surface of a flammable liquid first flashes in contact with fire. The flash point of a coating refers to the lowest temperature at which the vapor escaping from the coating product sample in the flash point cup can flash instantly in the presence of a flame.

The flash point of a coating is determined by the solvent in the coating, so it can usually be divided into three categories: A, B, and C based on the flash point of the solvent used in the coating. Class A: less than 28 ℃; Class B: 28-60 ℃; Class C: greater than 60 ℃.

The lower the flash point of the coating, the more likely it is to cause a fire, and the higher the risk factor. Therefore, increasing the flash point of the coating as much as possible is the key to ensuring safety.

The standard basis for the flash point of coatings currently implemented in China is GB/T5208-1985 "Rapid equilibrium method for the determination of flash point of coatings"

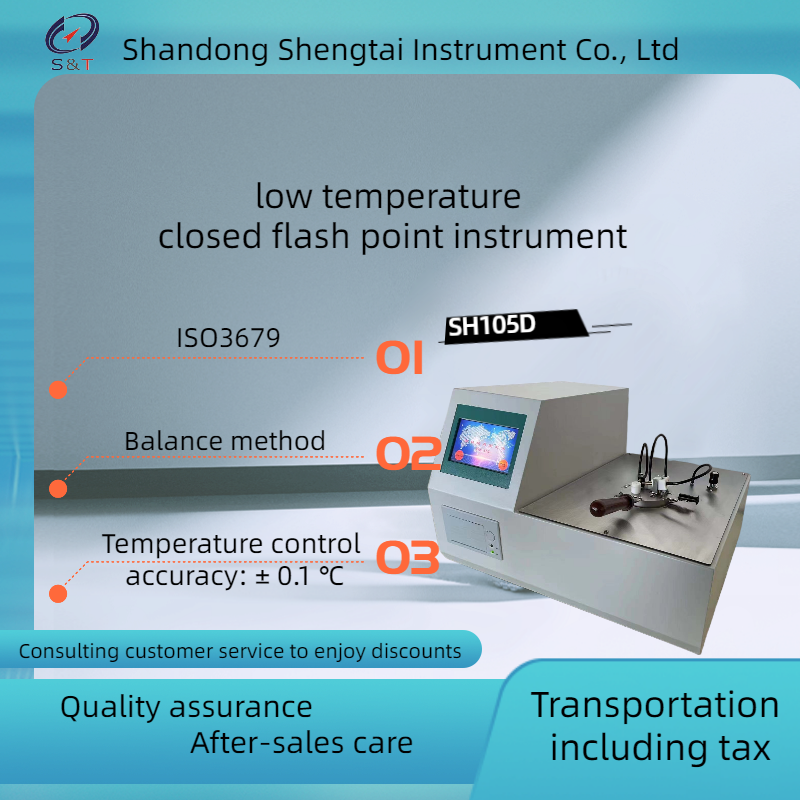

The application fields of coatings are very extensive, and can be seen everywhere in daily life. With the improvement of people's living standards, the call for a safer living environment is also increasing. The determination of paint flash point is an important indicator to ensure paint safety. Therefore, accurate, fast, stable, and accurate flash point testing instruments are very important. Therefore, Shengtai Instrument Co., Ltd.'s SH105D balance method low-temperature closed flash point instrument has emerged.

The SH105D equilibrium method low-temperature closed cup flash point instrument is designed and manufactured in accordance with the requirements specified in the Chinese standard GB/T 5208 "Rapid equilibrium closed cup method for the determination of flash point". This instrument also meets the requirements of ISO 3679 standard.

This instrument is particularly suitable for testing the flash point of various paints, paints, adhesives, solvents, petroleum, and related products with a closed cup flash point within the range of -30 ℃ to+100 ℃.